3D medical printing finds its footing in Dubai’s future

Launched in October 2015, Medativ is a Dubai-based 3D anatomical model printing company. The company name is a play on its products of “medical additive manufacturing”, says founder Mohamed Elawad.

“[When a] surgeon has a complex procedure, he would rely on medical imaging to understand the patient’s disease, think about a surgical approach,” explains Elawad. “But every patient is different. Medical images are 2D slices, black and white and on the screen. So you’re viewing them on a 2D plane…there’s no depth perception”.

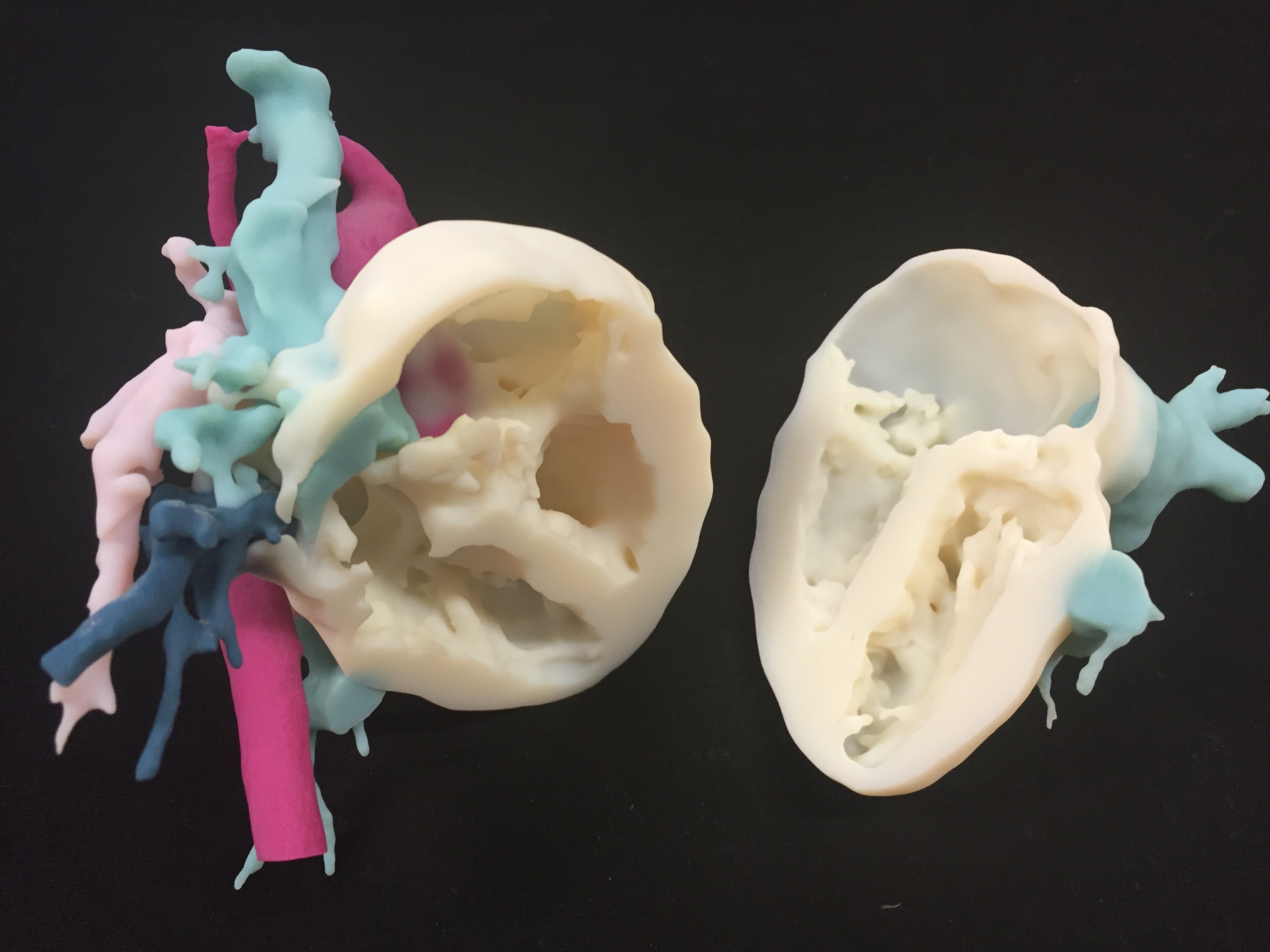

disease (Images via Medativ)

3D printed medical modeling changes that.

“When you give [surgeons] a patient specific model, the model is tactile [and gives] binocular inference. Like when you see a pair of shoes online, it’s much more different than when you check it out in store,” Elawad added.

Today, 3D printing has found its place in industries across the board – from construction to art to education, and to medicine. A civil engineer by trade, Elawad is quick to emphasize Medativ only offers anatomical modeling and not 3D organ implants. In other words, Medativ builds models based on medical imaging to improve patient outcomes and reduce costs.

3D anatomical modeling is especially useful during preoperative planning says Elawad because surgeons would know exactly what they’re doing and spend less time exploring. This leads to less pain and reduced blood loss for the patient. Most importantly, getting the operation right the first time means less complications in the future.

“Most surgeons are for it, but one of the obstacles is people don’t know about this technology,” Elawad tells Wamda. There is, therefore, a need to share benefits of the technology. Along with preoperative planning, Medativ helps build anatomical model libraries and teaching tools to educate future physicians.

To build the model, the Medativ team asks the physicians to fill out a form outlining the specific requirements and ultimate purpose of model. While they collaborate with surgeons from all medical fields, Elawad says cases of congenital heart disease have been very popular. Most recently, the team helped replace a dog’s kneecap in the United States, where Medativ also has a research team that includes radiologists working on evidence based solutions with 3D anatomical printing.

Medativ is also a part of the newly launched Dubai Future Accelerators (DFA). The 12-week accelerator program pairs government entities with early stage technology startups from around the world in order to “test solutions to seven key challenges of the future”.

Paul Smith, DFA’s head of program, called DFA “an experiment” at the launch press conference on October 5, 2016.

“The point of [the businesses] being here is to explore how their technology and the accesses of the government involved can create [solutions that are] more than the sum of its parts,” Smith said. “this program is not about trying to build a future in 12 weeks. The future that exists in 2030 and beyond is 1000 steps away, but we are trying to determine what those first few steps are.”

Medativ is tied to the Dubai Health Authority challenge of improving healthcare “using genomics, analytics, telepresence and personalized medicine”. With the city’s 3D printing strategy goals as well as its medical tourism hub ambitions, Medativ is at the intersection of an incredibly advantageous time for healthcare technology in Dubai.

“Startups have a difficult time penetrating infrastructure,” Elawad says. “Getting funding is one thing, getting business is even more difficult and so is proving your concept. [DFA] lets you prove your concept in real life in one of the best infrastructures in the world, which is quite unique.”

Medativ is a self-funded venture whose clients include tertiary hospitals in Saudi Arabia, physicians across the world as well as DHA.

Leave a Reply